When 200 people across Europe work on greener supply chains every day, a lot happens in a year, even outside of the typical day-to-day business.

We would therefore like to take you on a short journey through our year 2023 and present some highlights!

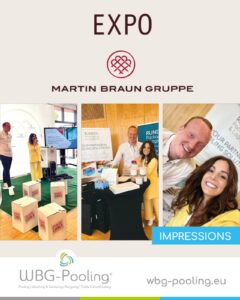

Right at the beginning, two major trade fairs came our way, and for the first time as exhibitors!

We presented our products and logistics concepts in close succession at FRUIT LOGISTICA in Berlin and BIOFACH in Nuremberg.

In addition to the volume reduction of load carriers, tracking using digital labels and platforms was also an exciting topic that we were able to inspire many visitors with.

We were present at both trade fairs together with companies from our parent company, the Runden Group.

We were also able to make excellent use of both events for an exchange with business partners – for example for the prototype of the “Eco Kiste”.

To round off what was already an intensive month, part of the team also visited the European Parliament in Brussels and took the opportunity to speak to some MEPs. The discussions focused primarily on the Packaging & Packaging Waste Regulation.

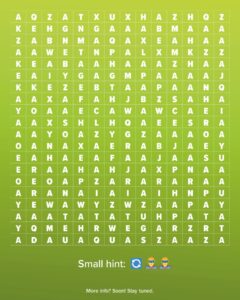

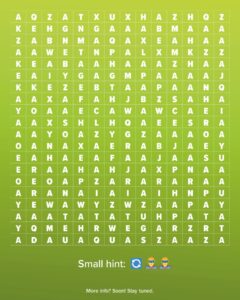

A big announcement was then due at the beginning of March – again, something we hadn’t done before, apart from the trade fairs.

However, we didn’t make the reveal quite so easy.

This was followed shortly afterwards by the dissolution: This year, we published our first German-language podcast called “MEHRWEG HEROES”. The aim: to raise awareness of circular economy issues.

The first episode went online on April 01, 2023.

But we’re not quite done with March yet: Internorga also took place this month and, of course, our category managers were there to find out about the latest trends and innovations in the sector.

At the end of April, we were then guests in Hamburg – where the “Branchendialog Fleisch & Wurst” organized by GS1 Germany took place, where we were able to visit BLOCK HOUSE production and listen to exciting keynote speeches.

In May, we were back in the Hanseatic city for the “Hamburger Logistik Tage” – together with other companies from the Runden Group, LHM-Pooling, Rubetrans Logistics and ecobyte, we exhibited here.

In June, our category managers held another interesting presentation for all participants at another event – this time focusing primarily on the baked goods sector.

Things continued in July with the LZ Strategietag Nachhaltigkeit & Verpackung.

And the next congress with a presentation was already on the agenda: Our Country Manager DE/AT/CH and Category Manager Fruit & Vegetables were on site at the German Fruit & Vegetable Congress in Düsseldorf.

As a pan-European pooling service provider, we naturally also went beyond national borders: at Fruit Attraction in Madrid, our German and Spanish colleagues were able to gain valuable insights.

Then there was the Austrian Summit for Retail & Branded Goods…

And the RIGA COMM…

…until all our international colleagues finally came together at ANUGA in Cologne! We were also exhibiting here for the first time this year and explained the economic and ecological benefits of reusable transport packaging in food supply chains.

Shortly afterwards, we were able to announce our second German-language podcast format, which focuses primarily on developments in the retail sector, more specifically food retail: RETAIL GUIDE.

While MEHRWEG HEROES is published weekly, there is always a new episode once a month on all podcast platforms and YouTube.

In October, our partner ecobyte also held an innovative, multi-day workshop with our load carriers. The main focus here was on the exchange of sensor data, low energy Bluetooth technology and full transparency within supply chains. This makes our reusable transport packaging smart and adds an important element to the already circular economy processes.

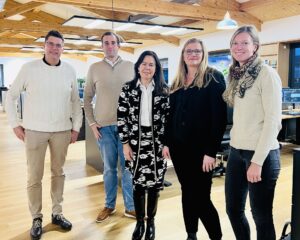

In November, we also had the pleasure of welcoming the Central Agency Packaging Register and taking the opportunity to discuss legal requirements.

In the same month, we went to the German Meat Congress in Mainz – where our Meat Category Managers Sofie Holt and Heinrich Kreymborg were also able to give a presentation on the opportunities of digital elements in supply chains with reusable transport packaging. Incidentally, we were able to exhibit here for the first time with a fresh logo.

Of course, our Spanish colleagues were also present at EMPACK.

We were able to experience the crowning glory of the year in the hectic pre-Christmas peak of the season – the handover of the converted car for Jonah in cooperation with Aktion Kinderträume e.V..

Instead of expensive customer gifts, we were able to put the money to good use and make everyday life much easier for one person.

The cooperation with the association of the German meat industry has existed for several years and is always something very special for us.

We can therefore look back on a thoroughly eventful year with many first-time experiences, great moments and fantastic development in many departments.

Follow us on LinkedIn, YouTube, Instagram and all podcast platforms to stay up to date!